Applications

Versatile. Modern. Innovative.

Product solutions from MAGNETEC provide reliable success in the most varied types of application.

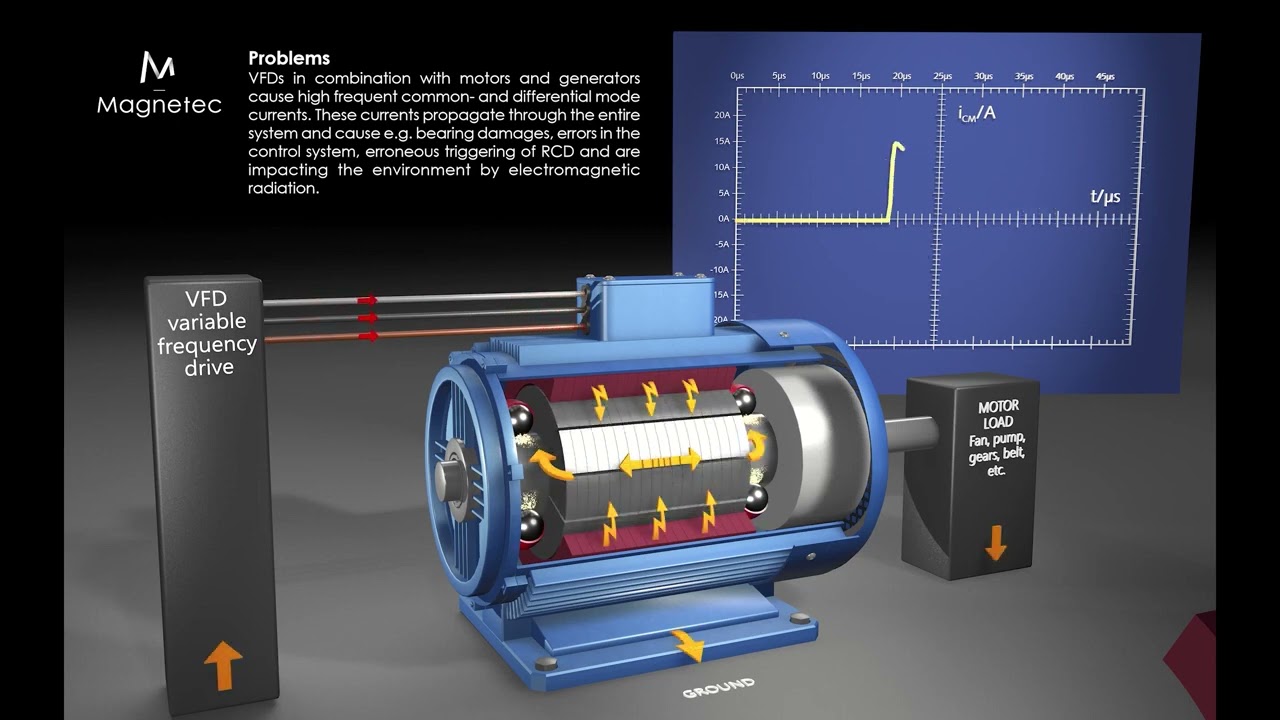

Thanks to the frequency converters (FC) with their constantly improving power electronics and control technology, modern drive systems have developed into a complex system. The possibility to switch high voltage with a few µs results in increasingly efficient frequency converters, however the electromagnetic interference also increases. A good circuit board layout and a good harmonization of hardware and software are essential EMC measures, although additional hardware must usually also be used. On the mains side, the high-frequency interference is usually suppressed with a mains filter to ensure mains cleanliness. Toward the motor/generator, very often only shielded cables are used. If connected appropriately for EMC (low impedance, etc.), they mostly reliably shield the radiated interference from other systems, but do not protect the motor/generator from line-conducted interference. The high-frequency asymmetrical interference flows from the FC to the motor/generator. For the frequencies in the high MHz range, the capacity of the motor/generator bearing is a low impedance return via ground. This described phenomenon results in motor/generator bearing currents that, in serious cases, can result in mechanical damage to the bearings. Even if this is not the case, the bearings, and thus also the lubricants, are also heated by the currents, which results in faster aging and higher maintenance costs.

CoolBlue® and NaLA® have established themselves as a low-cost and maintenance-free solution in many applications due to their good absorption of the interference and simple installation. We will be happy to support you with an on-site measurement, in combating/reducing/suppressing interference.

How may we help you?

Use our contact form for any questions associated with our extensive range of products and services. We will pass your inquiry directly on to your personal project advisor and will contact you soon!

We’re looking forward to hearing from you